Asset health management on MV switchgear

Want to mitigate the risks posed by your MV switchgear failing and leaving your plant without power when you need it most?

Pragma provides an engineering support service that provides:

- Improved MV switchgear availability

- Extended asset life

- Reduced business interruption risk

- Increased cost transparency and predictability

- Lower health, safety and environmental risk

Large industrial, mining, petrochemical, utilities and municipal owners are dependent on the reliability and availability of their MV switchgear to distribute and supply their plants or customers with electricity without interruption and to protect the network in case of faults. If MV switchgear fails, it can be catastrophic and lead to a loss of life, business and service delivery interruption, reduced income, brand equity and much more.

By continuously monitoring these assets you have factual and real-time information about the health of these assets and are able to make quick decisions and take action.

For us, it is more than just monitoring

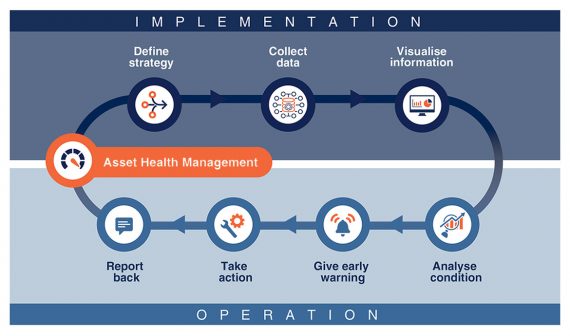

We follow an end-to-end implementation and operation’s approach to asset health management that includes a structured framework with asset type-specific features.

Our scope

Assets we cover

- MV switchgear

Industries we serve

- Manufacturing

- Mining

- Petrochemical

- Public Sector, Metros, Municipalities, Water boards

- Energy generation, transmission and distribution (incl. Renewable Energy)

Your challenges

Asset Reliability Risk

- Catastrophic failures including fires, gas emissions and explosions

- Consequential damage to equipment controlled by switchgear is potentially significant

- Business interruption is a major consequence of switchgear failure

Impact of poor maintenance practices

- Statutory compliance work not recorded

- Remedial work not managed

- Maintenance work quality not ensured

- Reduced asset reliability

Statutory and Safety Risk

- Significant risk human life in case of catastrophic failure or failure to function as electrical circuit protection and isolation

- Management of statutory requirements, incl. having panels and protection schemes verified, maintained and tested annually or in accordance to network regulations

- Poor compliance to regulatory or risk requirements (also for insurance)

Our value

Improved business sustainability

- Efficient implementation of digitalised maintenance processes

- Reduced business interruption risk through reliance on switchgear expert monitoring and advice

- Critical information provided to enable agile decision making

Switchgear availability assurance

- Continuous trending of asset condition parameters, incl. partial discharge, temperature, humidity, load and power quality

- Advanced diagnostics on-site to support fault finding efforts and take corrective action before failure

- Reactive and predictive maintenance work identified, planned and executed by expert field technicians

- Maintenance work inspected to ensure quality

- RCM based maintenance plans

Best-in-class monitoring solution

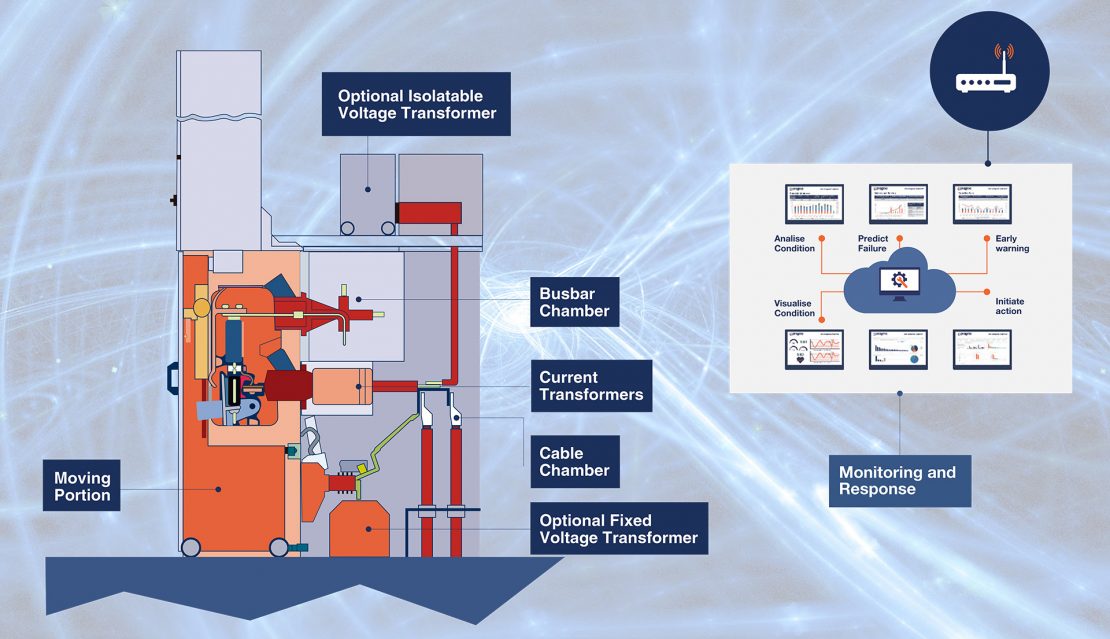

- Supply and installation of industry-leading monitoring technology

- Intelligent Gateway that bridges the gap between edge devices and the cloud irrespective of interfaces and protocols

- Use of cutting edge analytics to process asset condition data

- Web-based IoT monitoring platform for easy and remote access to condition parameters

Improved cost transparency

- Maintenance spend planned, benchmarked and controlled

- Asset life-cycle cost managed based on reliable information

- Reduced fixed-interval maintenance – only act when required

Focus on Switchgear

What we monitor

Temperatures

- Busbar

- Breaker

- Cable Terminations

Partial Discharge

- Busbar

- Circuit Breaker

- Cables Terminations

- Cable and Joints

- Connected equipment

System Health Monitoring

- Threshold and Alarm limits internal Self-Checking, with email and SMS communication

In-time Condition Monitoring

- Monitoring, Trending and Alarms

- PD (electrical discharges)

- Load conditions

- Switching Cycles/ Operations

- Diagnostics and Expert recommendation

- Confirmation after restorative action

- Web-based access to information and reports