Client Background

The client is the largest steel producer in Sub-Saharan Africa and a leader in major global markets, including construction, automation, and packing. Production is an integrated process where blast furnaces convert raw materials such as iron ore, coke and dolomite into liquid iron.

Electricity is used for many purposes in this kind of business, in this case, to operate various compressors. Should the client experience downtime of these compressors, the result would be a loss of production and severe repair or replacement costs.

These compressors are installed with Dynamic Ratings (DR) units for continuous monitoring. The client noticed an alarm on the unit, and Martec was called out for a comprehensive online PD assessment. PD analysis was conducted on the data obtained from the DR unit, and an assessment was performed using Aquila technology. The results revealed high partial discharge activity, verified through visual inspection.

Key Challenges

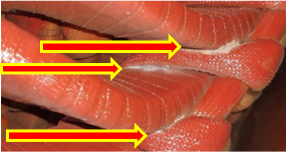

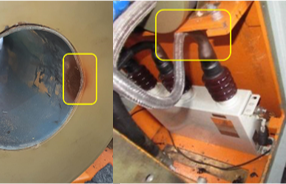

Clear evidence of discharges and deterioration was identified from the residue in the end-windings to carbon build-up in the termination box.

Clear evidence of discharges and deterioration was identified from the residue in the end-windings to carbon build-up in the termination box.

Martec Intervention

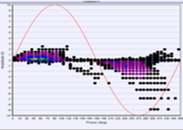

Phase-resolved and trend data was downloaded from the DR unit for analysis and to study the behaviour of the discharge activity over time. Due to the high PD activity, the more comprehensive Aquila technology was also used, utilising Aquila technology for in-depth analysis and correlation purposes. The findings prompted an investigation by visual inspection, revealing multiple PD sites that needed attention. Based on the visual findings, a final recommendation was made that the CT and Zorc leads must be re-installed under the quality assurance procedure.

Value add online assessment

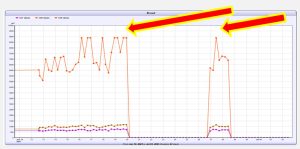

- Continuous monitoring saves a trend of the discharge behaviour over time and collects phase-resolved data periodically. In addition, this can alert the client and assist with in-depth analysis of detected activity.

- The online PD assessment was conducted using cost-effective Aquila technology, which identifies defects before they turn into failure.

- High PD signals were detected during the online condition assessment, which prompted an investigation to be conducted using visual inspection.

Value add visual inspection

Visual inspection is conducted for two reasons:

- Identify the location of the PD.

- And to determine the extent of the damage.

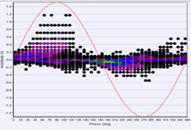

DR Qmax (mV) Trend – High PD

DR phase-resolved data

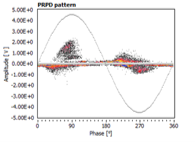

Aquilla phase-resolved data

Tools and technology used

- DR PD monitoring unit

- Aquila Technology

- Visual Inspections