Client Background

The client provides engineering services and a focused range of performance-enhancing atmospheric gases, welding, safety products, and LPG to valued customers. Given the criticality of the services offered by the client, MV components in all electrical networks must be kept to a highly reliable and maintainable standard to prevent premature failure.

Should the client experience downtime of this critical electrical plant, the result would be a loss of production and severe repair or replacement costs.

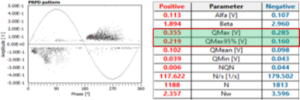

As a result, Martec conducted an online assessment using partial discharge assessment utilising PDFSA and Aquila technology to ascertain the condition of components in the 6.6kV system at Kuils River.

High discharges were detected from one compressor motor, which prompted further investigations.

Key Challenges

Often, internal defects can only be found when inspections are conducted during a maintenance shutdown. However, with Martec’s technology, the defects were detected and addressed before they reached critical levels or total breakdown.

The assessment depicted distinct PD signals with high intensities, prompting the necessity for visual inspection. Several wedges were found to be dislodged, as shown in the image below.

Martec Intervention

Martec conducted a comprehensive online PD assessment using the PDFSA and Aquila technologies.

High PD activity was detected from the motor compressor; the client was notified, and further investigation was carried out through visual inspection.

The inspection identified that several wedges were dislodged, corresponding with the delamination characteristics observed with the Aquila technology.

Value add

- An online assessment using the advanced Aquila and PDFSA technologies.

- Frequency domain analysis was utilised to identify the possible location of the PD activity within the system.

- The type and intensity of the PD activity were obtained from the time domains, and the terminations were risk-ranked accordingly.

Based on the findings from the online assessment, the compressor motor was deemed to be of high concern and further investigation was prompted.

Tools and technology used

- Aquila PD assessment technology

- Partial Discharge Frequency System Analyser (PDFSA)

- Visual inspections

- Investigations

- Corrective actions