Client Background

Our client operates a platinum mine in South Africa’s Limpopo province, covering 137km2. The present infrastructure comprises of five open pits. The mining method is truck-and-shovel, and current operating pit depths vary from 45m to 245m. Ore is milled at the on-mine North and South concentrators. In 2019, production of ore made them one of the largest platinum mines within Southern Africa.

As a reliable plant was a requirement, a condition-based maintenance tactic was adopted.

Martec was appointed to provide CM solutions for the medium voltage electrical assets at the concentrator plant that will ensure improved reliability and availability as well as compliance to insurance policies.

Key Challenges

Premature failure of Switchgear

The electrical network is of significant importance in driving production. The condition of the network, especially the switchgear, was not sufficiently assessed for risk of failure, meaning

that the electrical network posed a major risk.

Not only is a failure expensive to repair, but it also leads to unwanted and costly downtime (sometimes taking up to 3 – 5 days to repair), resulting in massive production losses.

Due to safety risks it was difficult to identify the suspected defective switchgear while the plant was in operation.

Martec opted to use online partial discharge technology, specifically signal analysis, to locate the source of discharges that compromised the reliability of this switchgear.

Martec Intervention

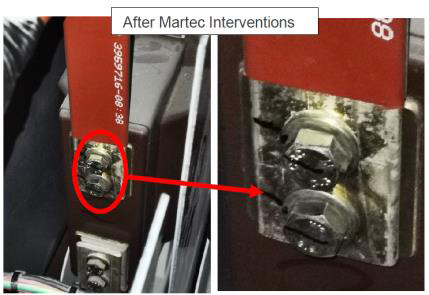

Online assessments were conducted in November 2019 and high risk levels were detected and assigned as Risk Level 5. Clear 3-phase contact discharges were identified using signal analysis. This indicated loose connections. An investigation was conducted in January 2020 during the next available shut down to locate and rectify the source(s) of the high discharges detected in this electrical network. The source of the discharges was found to be loose connections within a panel. These bolts were hand tightened and torqued and the high risk panel re-assessed to confirm if the repair was effective. Both panel and cable sections were merited as condition Level 2 after the repairs were conducted.

|  |

Value Add

- Reducing risk of failure

- Ensuring more reliable plant

- Restoration of a safe electrical system

- Ensuring safe working conditions within substations

- Saving in unwanted production losses

- Implementing a quality control process in repair

Eliminating PD sources

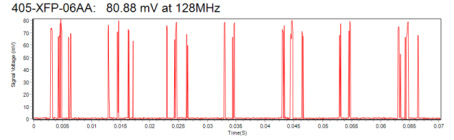

PDFSA Findings before shutdown

0-200MHz Frequency Domain

128MHz – Terminal Box area:

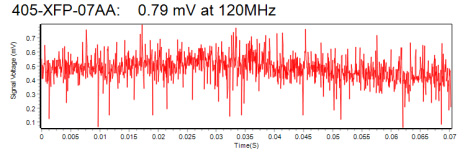

PDFSA Findings after corrective actions applied

0-200MHz Frequency Domain

120MHz – Terminal Box area:

Tools and Technology used

- Partial Discharge Frequency System Analyser(PDFSA)

- Ultra Sound Scanning

- Visual Inspections

- Investigations