Client Background

The client is the world’s leading primary producer of platinum group metals, with operations across the entire value chain from producer to producer and a complete range of PGMs. Given the criticality of production, MV components in all electrical networks must be kept to a highly reliable and maintainable standard to prevent premature failure.

Should the client experience downtime of this critical electrical plant, the result would be a loss of production and severe repair or replacement costs.

Thus, Martec needed to conduct online partial discharge testing utilising PDFSA and Aquila technology to ascertain the conditions of MV equipment in the 11kV system. Higher discharges were detected, which prompted further investigations.

Key Challenges

Often, internal defects can only be found when inspections are conducted during maintenance shutdown. However, with Martec’s technology, the defects were detected and addressed before they reached critical levels or total breakdown.

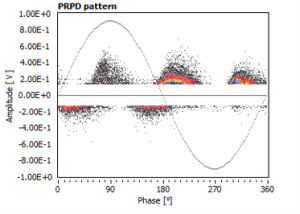

Multiple discharge events were identified, indicating more than one discharge source. Evidence of deterioration was observed from the Zorc leads, as depicted below.

Martec Intervention

Martec conducted a comprehensive online PD assessment using the Aquila technologies.

High PD activity was detected from the motor, the client was notified, and further investigation was carried out using visual inspection.

The inspection identified visible deterioration of the Zorc leads, corresponding with the three-phased discharge characteristics observed with the Aquila technology.

Value add online assessment – aquila and PDFSA

- An online assessment using advanced Aquila technologies.

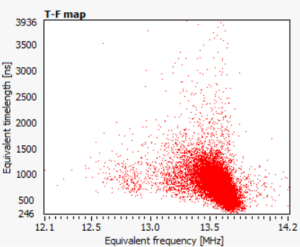

- TF-map is utilised to filter out noise and place focus on a specific partial discharge event.

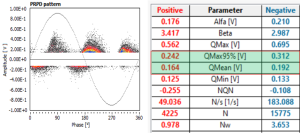

- PRPD pattern indicates what type of discharge activity was detected.

- Parameters indicate the severity of the detected activity.

- Based on the findings from the online assessment, these motors were recommended for further investigation.

Tools and technology used

- Aquila PD assessment technology

- Visual inspections