Client Background

The client operates throughout the entire value chain to produce a full range of PGMs, including platinum, palladium, rhodium, iridium, ruthenium, and osmium, with various sites assigned to each production stage.

Should the client experience downtime in any of the electrical plants, the result would be a loss of production and severe repair or replacement costs.

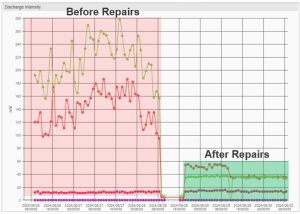

Martec observed an increase in the PD trend on one of the client’s compressor motors. This was detected by the intime monitoring system installed at the client site. Qmax milli-volts(mV) intensities from the 80pF PD couplers installed at the line terminals of the compressor motor were trending at high values.

Key Challenges

Given the plant’s critical nature, shutting down the compressor motors for visual inspections is quite challenging. Therefore, online PD assessments are essential for monitoring the condition of MV motor and cable insulation systems.

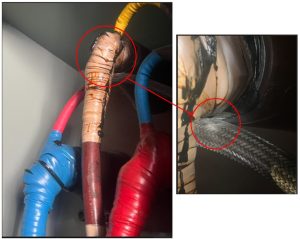

The visual inspection identified PD activity on one of the Zorc leads in contact with the white phase connection bushing. This correlated with the PRPD pattern detected with the online PD assessment.

Martec Intervention

- Martec noted an increasing trend from the permanent monitoring system and notified the client.

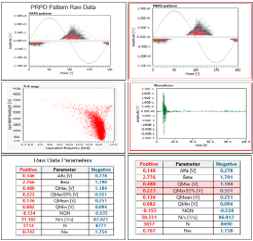

- Martec conducted an advanced online PD assessment using Aquila technology. The assessment revealed high PD activity

- A visual inspection followed, and signs of PD on the motor Zorc leads were identified.

- Corrective measures were taken, resulting in a notable reduction in PD levels after the repairs.

Value Add Online Assessment

- Intime permanent PD monitoring system (IoT).

- Advanced Aquila technology, which utilises the TF map to separate background noise for PD signals.

- The type of PD activity identified through analysis of Phase-resolved patterns.

- Parameters such as Qmax and pulse count determine the intensity of the PD activity.

Tools and technology used

- Permanent online PD monitoring system

- Aquila PD assessment technology

- Visual inspections