Client Background

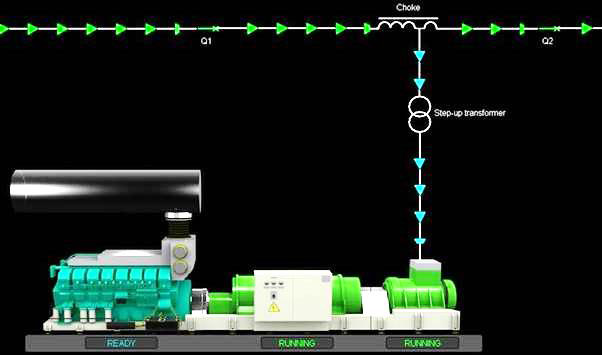

A failure of the DRUPPS unit 2 reactor led to an investigation and online condition assessment of all the units (1 to 10). Advanced online condition assessments were conducted on the switchgear, reactors and cast resin transformer terminations to determine the risk of further failures.

Unit 2 reactor feeder cables were replaced and an investigation of the old terminations was conducted. The outer anti-tracking tubes of the terminations showed signs of excessive deterioration and tracking caused by electrical discharges.

Online assessment and investigations of the terminations showed that the terminations had not been installed to the required specifications and the resultant premature deterioration (shortened life) would lead to catastrophic failures.

Key Challenges

Premature failure of the plant

The challenges were to identify and rank the risk of failure caused by the defects (electrical discharges) with plans to avoid premature failure that can lead to long downtime.

Quality of supply

Because of operational requirements, only one unit can be removed from service, therefore the planning and use of the online technology assessment risk ranking findings are key to the success of timeous replacement of the feeder cables and terminations.

Quality and safety

The replacement of the cable and terminations must be done while the rest of the plant is in operation. Safety is the first priority and the replacements must be done with adherence to strict safety and quality assurance processes.

Martec Intervention

- Conduct online condition assessment of the medium voltage network that provides knowledge of the condition of the electrical components, such as those in urgent need of replacement, components that can be replaced during routine maintenance or components that are healthy.

- Conduct root cause analysis of the medium voltage components to eliminate the implementation of the same type of defects.

- Implement a predictive maintenance system through an SLA clearly stating the scope of work, periodic intervention, permanent or periodic monitoring process and KPI.

- The Pragma technical condition monitoring team being part of the maintenance process (in this case supporting predictive maintenance) adds value for Nampak Glass as:-

- condition monitoring is the key focus of trained staff in advanced online and offline

- technologies with the back-up of international principals

- they are specialised in medium/high voltage condition assessments in all types of industries

Value add

- Quality of supply – this is the key to improve performance for Nampak Glass.

- Permanent online and periodic monitoring of the MV power system assets will identify early defects.

- Reliability of rectification work is assured by strict quality systems.

- Implementation of a service level agreement (SLA) ensures predictive maintenance plans are implemented and asset risk is well managed by periodic online assessments at appropriate intervals.

- Electrical defects can be located, identified and repaired in the early stages to avoid excessive cost and downtime of the plant.

Tools and technology

- Repair and replacement of defects that can lead to failure.

- Advanced online condition assessment technology will identify, locate and quantify the defects to be repaired during maintenance schedules.

- Advanced offline technologies and visual inspections will add to the predictive maintenance plans.